Fluidized Bed Drying Equipment for Aluminium Hydroxide

Tags:

Overview: WORKING PRINCIPLE: The working principle of fluid-bed dryer is that materials go into the machine from feed inlet. Under the vibratory force, the materials are thrown along the horizontal fluid bed and move forward continuously...

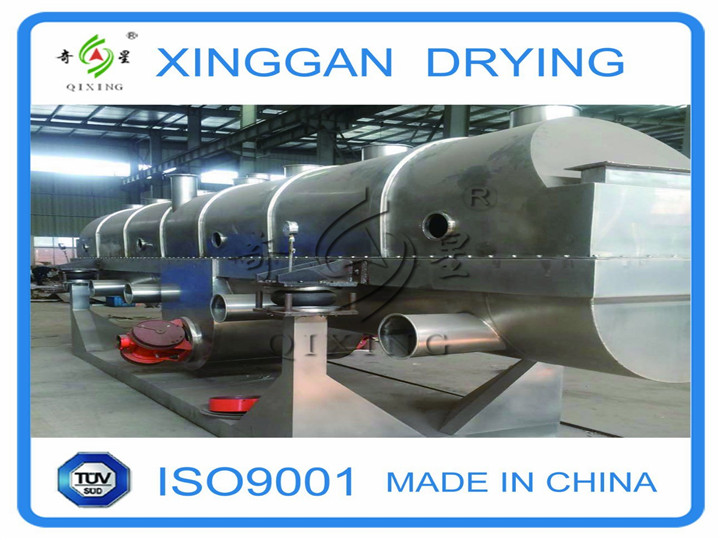

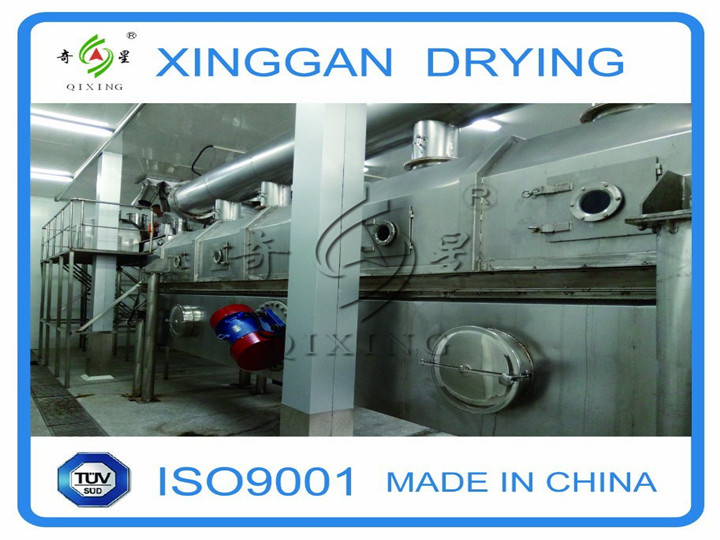

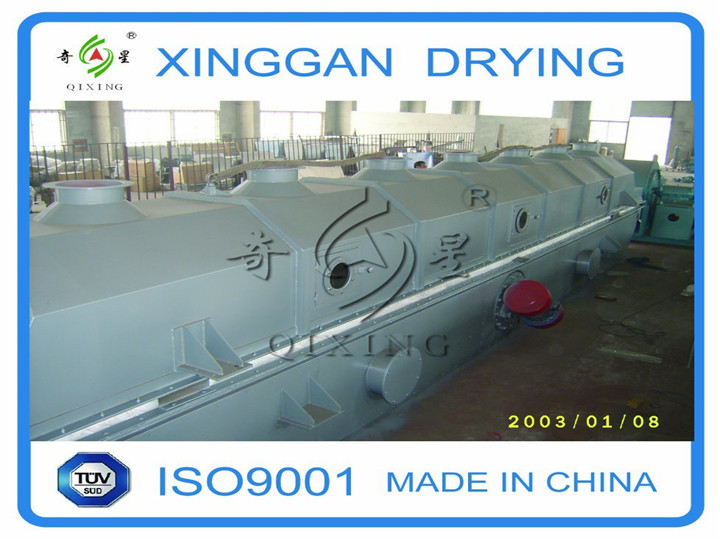

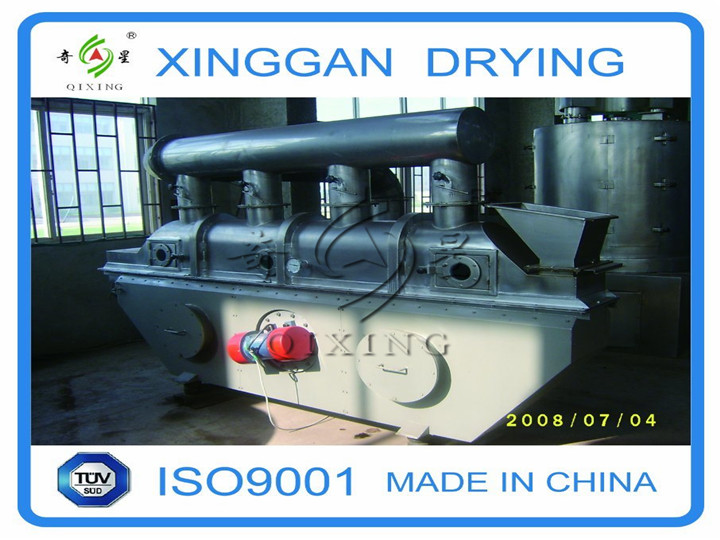

Detail Images

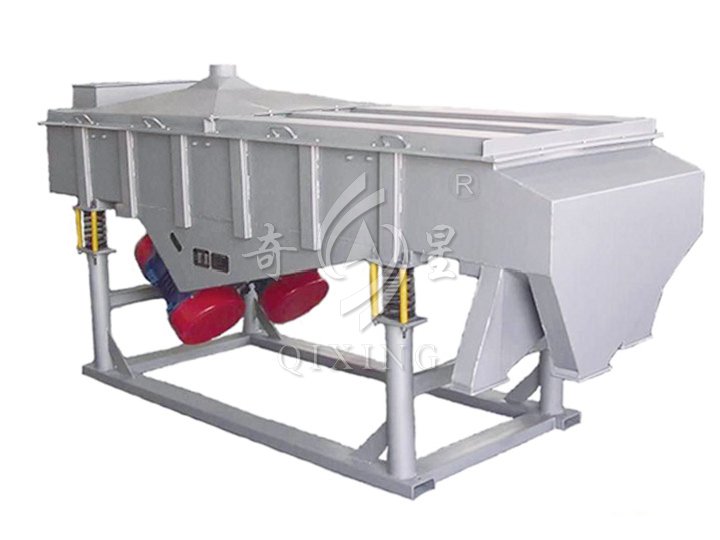

WORKING PRINCIPLE

The working principle of fluid-bed dryer is that materials go into the machine from feed inlet. Under the vibratory force, the materials are thrown along the horizontal fluid bed and move forward continuously. After the hot air goes upward through the fluidized bed and a heat exchange with wet materials, the wet air is dedusted by cyclone separator and then discharged from air exhaust in 1:3.

FEATURES

1. Vibration source is driven by vibration motor, smooth operation, easy maintenance, low noise, long life.

2. Fluidized symmetry, no dead gaps and broken phenomenon, which enable uniform dried and cooled products

3. Adjustable, wide scope of application. Material thickness, speed of movement within the machine and total amplitude can all achieve stepless adjustment.

4. Small damage to the surface of the material, available for drying of friable material, when irregular particles will not affect work results.

5. Totally enclosed structure, effectively preventing cross infection between the material and the air. Clean working environment.

6. High mechanical efficiency and thermal efficiency, perfect energy-saving effect with 30 %-60 % energy saved comparing with average drying devices.

APPLICATION

This dryer is widely used for drying, cooling, wetting of the products in light industry, chemical industry, pharmaceutical industry, foodstuff, and etc.

APPLICABLE MATERIALS

This machine is applicable for drying and cooling powdery and granular materials in chemical, pharmaceutical, food, dehydrated vegetables, grain, mineral and other industries. Such as: citric acid, monosodium glutamate, borax, ammonium sulfate, compound fertilizer, shredded radish, soybean meal, distillers grains, seeds, slag, sugar and so on.

The working principle of fluid-bed dryer is that materials go into the machine from feed inlet. Under the vibratory force, the materials are thrown along the horizontal fluid bed and move forward continuously. After the hot air goes upward through the fluidized bed and a heat exchange with wet materials, the wet air is dedusted by cyclone separator and then discharged from air exhaust in 1:3.

FEATURES

1. Vibration source is driven by vibration motor, smooth operation, easy maintenance, low noise, long life.

2. Fluidized symmetry, no dead gaps and broken phenomenon, which enable uniform dried and cooled products

3. Adjustable, wide scope of application. Material thickness, speed of movement within the machine and total amplitude can all achieve stepless adjustment.

4. Small damage to the surface of the material, available for drying of friable material, when irregular particles will not affect work results.

5. Totally enclosed structure, effectively preventing cross infection between the material and the air. Clean working environment.

6. High mechanical efficiency and thermal efficiency, perfect energy-saving effect with 30 %-60 % energy saved comparing with average drying devices.

APPLICATION

This dryer is widely used for drying, cooling, wetting of the products in light industry, chemical industry, pharmaceutical industry, foodstuff, and etc.

APPLICABLE MATERIALS

This machine is applicable for drying and cooling powdery and granular materials in chemical, pharmaceutical, food, dehydrated vegetables, grain, mineral and other industries. Such as: citric acid, monosodium glutamate, borax, ammonium sulfate, compound fertilizer, shredded radish, soybean meal, distillers grains, seeds, slag, sugar and so on.

News

- 2018-05-11 > Tow CT-C Hot Air Circulation Ovens Manufactured by Our Company Were Exported to Bangladesh

- 2018-04-25 > 2018 (Spring) China International Pharmaceutical Machinery Exposition

- 2018-02-23 > New Year Begins a New Journey

- 2017-10-04 > 2017(Autumn) Professional Pharmaceutical Machinery Exhibition in China

- 2017-06-24 > Xinggan Drying Successfully Participated in the 17th Pharmaceutical Raw Materials Exhibition

- 2017-04-22 > 2017(Spring) Professional Pharmaceutical Machinery Exhibition in Qingdao

Products