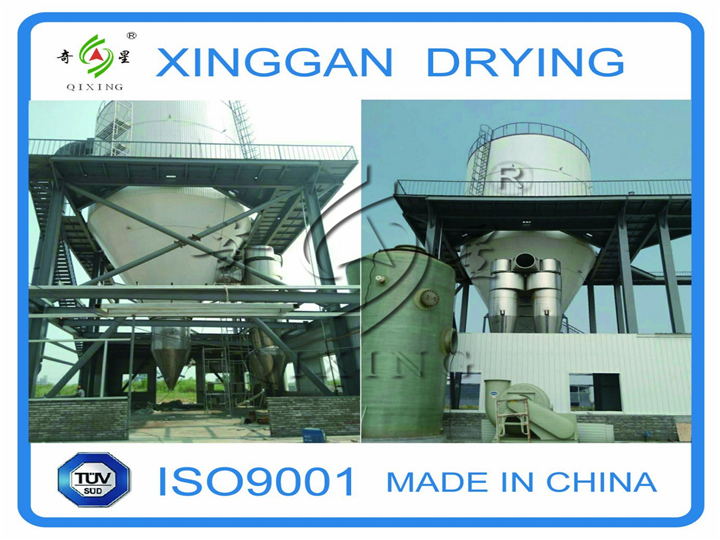

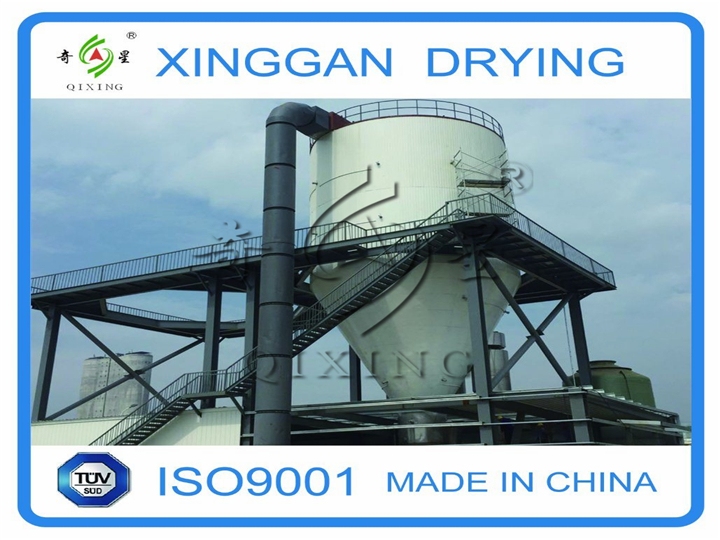

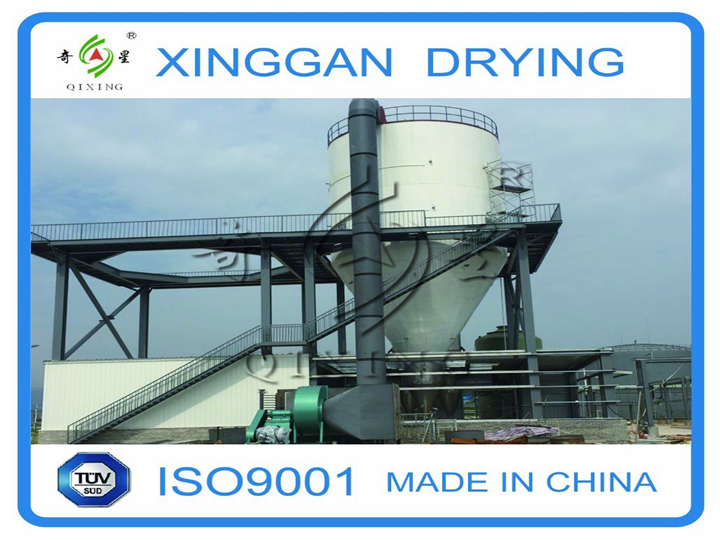

Spray Drying Equipment for Polyaluminium Chloride

Tags:

Class: Spray Dryer Production Line

Overview: Polymetric Chloride Aluminum is commonly known as a water purifying agent or coagulant, which is a water-soluble inorganic polymer between ALCL3 and AL (OH) 3. The chemical formula is [AL2(OH)nCl6-nLm]. M represents the degree of polymerization...

Detail Images

Polymetric Chloride Aluminum is commonly known as a water purifying agent or coagulant, which is a water-soluble inorganic polymer between ALCL3 and AL (OH) 3. The chemical formula is [AL2(OH)nCl6-nLm]. M represents the degree of polymerization, and n represents the neutrality of the PAC product. The color is yellow or light yellow, dark brown and dark gray. It is resinous solid. The product has a strong bridging adsorption performance. In the process of hydrolysis, it is accompanied by condensation, adsorption and precipitation and other physical and chemical processes. The basic difference between polyaluminum chloride and traditional inorganic coagulant is that the traditional inorganic coagulant is a low molecular crystal salt, the structure of polyaluminum chloride is composed of polymorphic carboxyl complex, the flocculation and sedimentation speed is fast, having wide PH value range, no corrosive in the pipe, having obvious water purification effects, and so on. The product is widely used in drinking water, industrial water and sewage treatment field.

Due to the stability, high hydrolysis speed and adsorption capacity, fast dense mass precipitation, low water turbidity, dehydration and other advantages of spray drying, under the same condition of water quality, the addition of aluminum chloride is reduced, especially in the case of poor water quality. The amount of spray-dried products is reduced to half compared to drum-dried polyaluminum chloride. This not only reduces the labor intensity of workers, but also reduces user's water costs. In addition, the use of spray-dried products can ensure safety, reduce water accidents.

Polymetric aluminum chloride use the most advanced production technology with using high-quality raw materials from the polymerization reaction. Production is according to the national standard GB15892-2009 requirements. Polymetric aluminum chloride is processed by spray drying process, so it can also be called high-grade spray-dried polymetric aluminum chloride.

Due to the stability, high hydrolysis speed and adsorption capacity, fast dense mass precipitation, low water turbidity, dehydration and other advantages of spray drying, under the same condition of water quality, the addition of aluminum chloride is reduced, especially in the case of poor water quality. The amount of spray-dried products is reduced to half compared to drum-dried polyaluminum chloride. This not only reduces the labor intensity of workers, but also reduces user's water costs. In addition, the use of spray-dried products can ensure safety, reduce water accidents.

Polymetric aluminum chloride use the most advanced production technology with using high-quality raw materials from the polymerization reaction. Production is according to the national standard GB15892-2009 requirements. Polymetric aluminum chloride is processed by spray drying process, so it can also be called high-grade spray-dried polymetric aluminum chloride.

News

- 2018-05-11 > Tow CT-C Hot Air Circulation Ovens Manufactured by Our Company Were Exported to Bangladesh

- 2018-04-25 > 2018 (Spring) China International Pharmaceutical Machinery Exposition

- 2018-02-23 > New Year Begins a New Journey

- 2017-10-04 > 2017(Autumn) Professional Pharmaceutical Machinery Exhibition in China

- 2017-06-24 > Xinggan Drying Successfully Participated in the 17th Pharmaceutical Raw Materials Exhibition

- 2017-04-22 > 2017(Spring) Professional Pharmaceutical Machinery Exhibition in Qingdao

Products