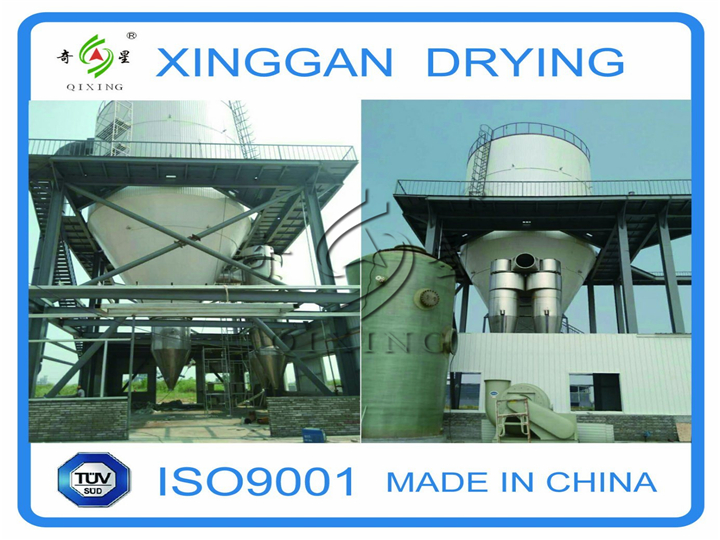

Spray Drying Equipment for Catalysts

Tags:

Class: Spray Dryer Production Line

Overview: WORKING PRINCIPLE: Filtered and heated air goes into air distributor on the top of the dryer, and spirals into drying room uniformly. Going through the high-speed centrifugal atomizer on the top of tower, the liquid (rotates) sprays into extremely...

Detail Images

WORKING PRINCIPLE

Filtered and heated air goes into air distributor on the top of the dryer, and spirals into drying room uniformly. Going through the high-speed centrifugal atomizer on the top of tower, the liquid (rotates) sprays into extremely fine mist liquid beads, and can be dried completely in a short time in co-current contact with hot air. Finished products exhaust continuously from the bottom of the drying tower and cyclone separator, while waste gases are vented by the fan.

FEATURES

1. Fast drying speed; greatly increasing the surface area of the material after the liquid is atomized; it can instantly evaporate 95% -98% of water in the stream of hot air; it takes only a few seconds to complete drying, which is especially suitable for drying heat sensitive materials.

2. Our products have a good uniformity, mobility and solubility, high purity and good quality.

3. Simplified production process, easy to operate and control. Liquid of 40-60% moisture content (up to 90% for special materials) can be dried into powder products at a time, without crushing and screening after drying, which reduces production process and improve product purity. The size, bulk density, moisture can be adjusted within a certain range by changing operation conditions. It is convenient to do control and management.

APPLICATION

Chemical industry: sodium fluoride (potassium), alkaline dyestuff and pigment, dyestuff intermediate, compound fertilizer, formaldehyde silicic acid, catalyst, sulphuric acid agent, amino acid, white carbon black, etc.

Plastic resin: AB, ABS latex, urea resin, phenolic resin, dense glue (urea) formaldehyde resins, polyethylene, polyvinyl chloride, etc.

Food industry: fat-rich milk powder, lancet protein, cocoa milk powder, babymeal, hunting blood meal, egg white (yellow), etc.

Food and plants: oats, chicken juice, coffee, instant tea, seasoning meat, protein, soybean, peanut protein, hydrolyzate and so on.

Sugar: corn syrup, corn starch, glucose, pectin, malt sugar, potassium sorbate, etc.

Ceramics: aluminium oxide, ceramic tile material, magnesium oxide, talcum powder, etc.

Filtered and heated air goes into air distributor on the top of the dryer, and spirals into drying room uniformly. Going through the high-speed centrifugal atomizer on the top of tower, the liquid (rotates) sprays into extremely fine mist liquid beads, and can be dried completely in a short time in co-current contact with hot air. Finished products exhaust continuously from the bottom of the drying tower and cyclone separator, while waste gases are vented by the fan.

FEATURES

1. Fast drying speed; greatly increasing the surface area of the material after the liquid is atomized; it can instantly evaporate 95% -98% of water in the stream of hot air; it takes only a few seconds to complete drying, which is especially suitable for drying heat sensitive materials.

2. Our products have a good uniformity, mobility and solubility, high purity and good quality.

3. Simplified production process, easy to operate and control. Liquid of 40-60% moisture content (up to 90% for special materials) can be dried into powder products at a time, without crushing and screening after drying, which reduces production process and improve product purity. The size, bulk density, moisture can be adjusted within a certain range by changing operation conditions. It is convenient to do control and management.

APPLICATION

Chemical industry: sodium fluoride (potassium), alkaline dyestuff and pigment, dyestuff intermediate, compound fertilizer, formaldehyde silicic acid, catalyst, sulphuric acid agent, amino acid, white carbon black, etc.

Plastic resin: AB, ABS latex, urea resin, phenolic resin, dense glue (urea) formaldehyde resins, polyethylene, polyvinyl chloride, etc.

Food industry: fat-rich milk powder, lancet protein, cocoa milk powder, babymeal, hunting blood meal, egg white (yellow), etc.

Food and plants: oats, chicken juice, coffee, instant tea, seasoning meat, protein, soybean, peanut protein, hydrolyzate and so on.

Sugar: corn syrup, corn starch, glucose, pectin, malt sugar, potassium sorbate, etc.

Ceramics: aluminium oxide, ceramic tile material, magnesium oxide, talcum powder, etc.

News

- 2018-05-11 > Tow CT-C Hot Air Circulation Ovens Manufactured by Our Company Were Exported to Bangladesh

- 2018-04-25 > 2018 (Spring) China International Pharmaceutical Machinery Exposition

- 2018-02-23 > New Year Begins a New Journey

- 2017-10-04 > 2017(Autumn) Professional Pharmaceutical Machinery Exhibition in China

- 2017-06-24 > Xinggan Drying Successfully Participated in the 17th Pharmaceutical Raw Materials Exhibition

- 2017-04-22 > 2017(Spring) Professional Pharmaceutical Machinery Exhibition in Qingdao

Products