SZG Series Double-cone Rotary Vacuum Dryer

SZG Series Double-cone Rotary Vacuum Dryer

SZG Series Double-cone Rotary Vacuum Dryer

INTRODUCTION

INTRODUCTION

SZG double-cone rotary vacuum dryer is a new generation drying apparatus our company developed on the basis of technology of domestic similar products. It uses belt-chain two elastic coupling manner thus it runs smoothly. Specially designed technology fully reflects two good concentric shafts.Heating medium and vacuum system use reliable vacuum system use reliable mechanical seal or US-technology rotary joint, on which basis we have developed SZG-A, with stepless speed regulating and constant temperature control. We also supply hundreds sets to the customers every year. As for working medium, it may be thermal oil or steam or hot water. For drying the adhesive raw materials, we have designed specially a stirring palate butter for you.

WORKING PRINCIPLE

◎ When the heat source (hot water, low temperature steam, or thermal oil) pass through the sealed jacket, the heat will be transmitted to raw material through the inner shell.

◎ Under action of driving power, the tank is rotated slowly and the raw material is mixed continuously. The purpose of reinforced drying can be realized.

◎ The raw material is under vacuum condition. When steam pressure is dropping, it makes the moisture (solvent) at the surface of raw material become saturation and then evaporates. The solvent will be discharged through vacuum pump.

◎ The moisture (solvent) of raw material will infiltrate. Evaporate and discharge continuously.The production processes are carried out continuously and the drying can be done in a short time.

FEATURES

◎ Automatic constant temperature control is used when the oil is heating.Biochemical products and raw materials can be dried, in a temperature between 20-160℃.

◎ High thermal efficiency, more than 2 times improvement than average oven.

◎ Indirect heating so that the material will not be contaminated. In line with “GMP” requirements. Simple equipment maintenance. Easy to clean.

◎ Using recommended resettlement process demonstration solvent to recover resettlement.

APPLICAITON

Concentration, mixing and drying of powder, granular materials and fibers of chemical, pharmaceutical and food industries:Materials requiring low-temperature drying(such as biological products). Being suitable for drying materials which are easily oxidized, volatile, heat-sensitive, strong irritant, toxic or not permitted to destroy its crystals.

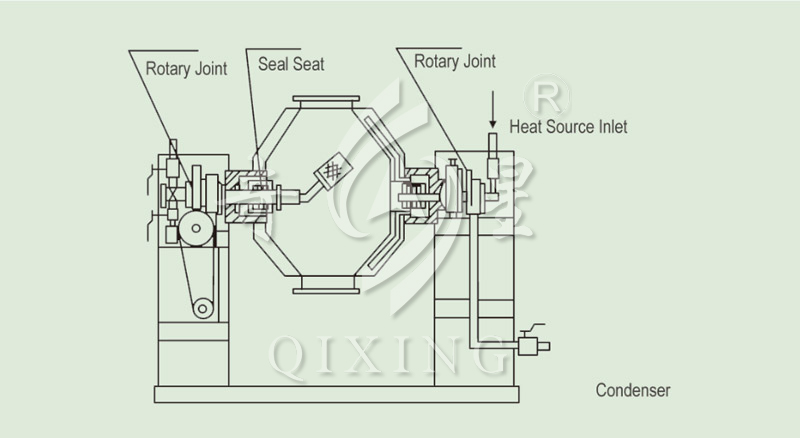

STRUCTURE SCHEMATIC

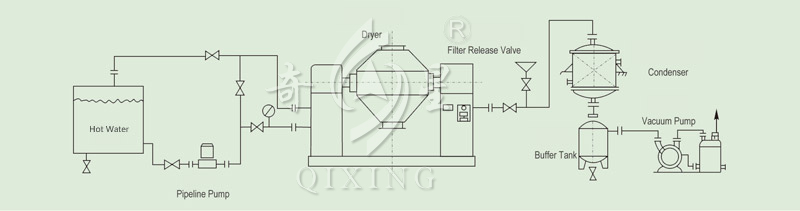

PROCESS FLOW

TECHNICAL PARAMETERS

|

Item\Model |

SZG-100 |

SZG-350 |

SZG-500 |

SZG-750 |

SZG-1000 |

SZG-1500 |

SZG-2000 |

SZG-3500 |

SZG-4500 |

SZG-5000 |

|

Inside Volume of Tank(L) |

100 |

350 |

500 |

750 |

1000 |

1500 |

2000 |

3500 |

4500 |

5000 |

|

Practical Loading Volume (L) |

≤50 |

≤175 |

≤250 |

≤375 |

≤ 500 |

≤750 |

≤1000 |

≤1750 |

≤2250 |

≤2500 |

|

Heatint Area(m2)

|

1.16

|

2

|

2.63

|

3.5

|

4.61

|

5.58

|

7.5

|

11.2

|

13.1

|

14.1

|

|

Rotary Speed(r.p.m.) |

4-6

|

|||||||||

|

Power of Motor(kw) |

0.75 |

1.1 |

1.5 |

2 |

3 |

3 |

4 |

5.5 |

7.5 |

11 |

|

Occupied Area LxW(mm) |

2160 x800 |

2260 x800 |

2350 x800 |

2560 x1000 |

2860 x1300 |

3060 x1300 |

3260 x1400 |

3760 x1800 |

3960 x2000 |

4400 x2500 |

|

Rotating Height (mm) |

1750 |

2100 |

2250 |

2490 |

2800 |

2940 |

2990 |

3490 |

4100 |

4200 |

|

Design Pressure for Inside of Tank (MPa) |

-0.1-0.15 |

|||||||||

|

Design pressure of jacket (MPa) |

≤0.3 |

|||||||||

|

Working Temperature(°C) |

Ttank Inside≤85 Jacket≤140 |

|||||||||

|

Model of Vacuum Pump(with condenser)

|

2X-15A

|

2X-15A

|

2X-30A

|

2X-30A

|

2X-70A

|

JZJX300-8

|

JZJX300-4

|

JZJX600-8

|

JZJX600-4

|

JZJX300-4

|

|

Model Power

|

2KW

|

2KW

|

3KW

|

3KW

|

505KW

|

7KW

|

9.5KW

|

11KW

|

20.5KW

|

22KW

|

|

Power of Vacuum |

SK-0.4 |

SK-0.4 |

SK-0.8 |

SK-1.5 |

SK-1.5 |

SK-3 |

SK-6 |

SK-6 |

SK-9 |

SK-12 |

|

Model Power

|

1.5KW |

2.2KW |

2.2KW |

4KW |

4KW |

5.5KW |

11KW |

11KW |

15KW |

18.5KW |

|

Weight (kg) |

800 |

1100 |

1200 |

1500 |

2800 |

3300 |

3600 |

6400 |

7500 |

8600 |

Notes: The volume coefficient of the material before and after drying is greatly increased or reduced.

- 2018-05-11 > Tow CT-C Hot Air Circulation Ovens Manufactured by Our Company Were Exported to Bangladesh

- 2018-04-25 > 2018 (Spring) China International Pharmaceutical Machinery Exposition

- 2018-02-23 > New Year Begins a New Journey

- 2017-10-04 > 2017(Autumn) Professional Pharmaceutical Machinery Exhibition in China

- 2017-06-24 > Xinggan Drying Successfully Participated in the 17th Pharmaceutical Raw Materials Exhibition

- 2017-04-22 > 2017(Spring) Professional Pharmaceutical Machinery Exhibition in Qingdao