PLG Series Tray Continuum Dryer

PLG Series Tray Continuum Dryer

PLG Series Tray Continuum Dryer

INTRODUCTION

INTRODUCTION

PLG Tray Continuum Dryer is a kind of high-efficiency transmission-type equipment for continuous drying. Its unique structure and WORKING PRINCIPLE determine its characteristics of high thermal efficiency, low energy consumption, small land occupation, simple configuration, convenient control and good operating environment. It is widely used in drying of industries of chemical, pharmaceutical, pesticide, food, forage, agricultural processing and so on.

WORKING PRINCIPLE

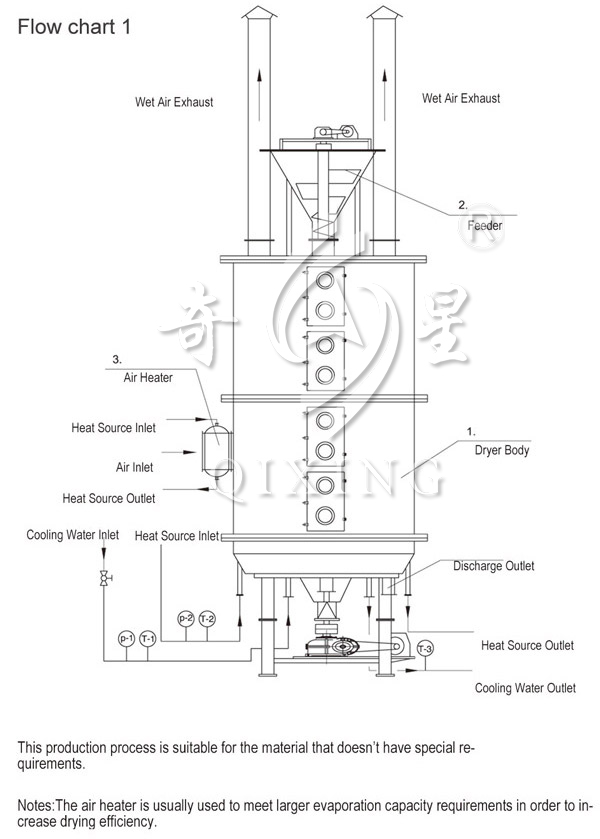

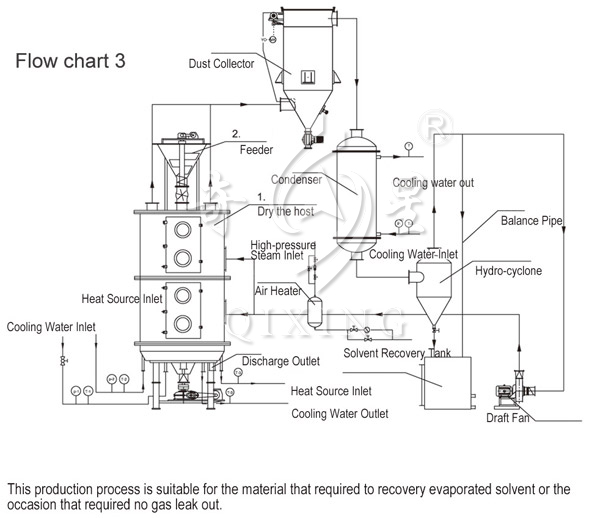

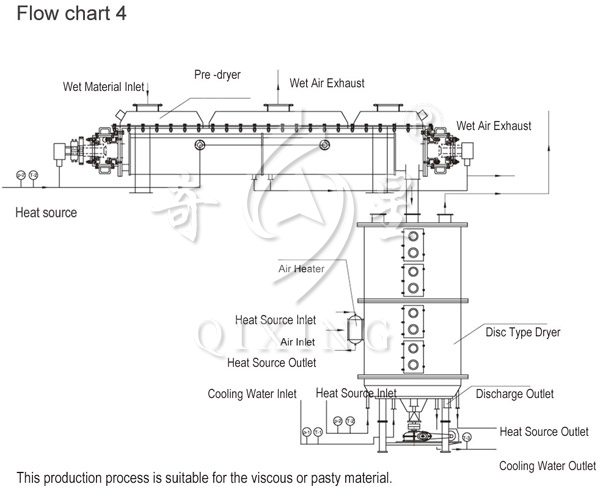

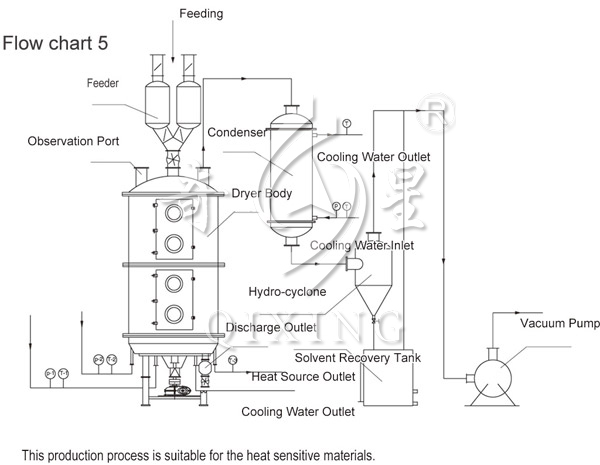

Wet materials are continuously fed by feeder onto the drying tray on the first layer of upper portion of the dryer; rake arm with rake on it will make rotary movement to continuously stir the materials. Along the index spiral line, the materials flow through the surface of the drying tray. Materials in the small plate are transferred to the outer edge, where they fall onto the outer edge of big plate below. In the big plate the materials move to the inside and fall onto the small plate on the next layer from the mouth in the middle. Small and big plates are arranged up and down alternatively, making the materials flow through the whole dryer consistently. In the form of saturated steam, hot water or thermal oil, heating medium are pumped into the hollow drying tray, entering from one end and exported from the other end. Dried materials fall into the bottom and are transferred to the outlet by rake and then discharged. The moisture escapes from the materials and exhausts from the outlet at the top. Moisture in vacuum tray dryer is exhausted from vacuum pump on the top. The dried materials discharged from bottom can be packed directly. By equipping auxiliary equipment such as finned heater, solvent recovery condensers, sack-duster, dry material backmixer and induced draft fan, its drying capacity can be increased, and it can be used to dry paste and heat-sensitive materials and operate heat decomposition and reaction, meanwhile more easily recovering solvent.

FEATURES

(A) Easy regulation and good applicability

◎ By adjusting the thickness of bed of material, rotate speed of main spindle, number of rake arms, type and size of rakes, the drying process can achieve the best.

◎ Each layer of drying tray can be respectively pumped into hot medium or cold medium, heating or cooling the materials. The material temperature control is accurate and easy.

◎ The residence time of materials can be accurately adjusted.

◎ Single flow of material without back-mixing; even drying and stable quality, no need to re-mix.

(B) Simple and easy operation

◎ Starting and closing operation of dryer is simple.

◎ When feeding stops, the rake can quickly empty the dryer.

◎ Through a special endoscope large inspection door, it is possible to have a very carefully cleaning and observation within the device.

(C) Low energy consumption

◎ Thin layer of materials, low rotate speed of main spindle. Material delivery system needs small power and less power consumption.

◎ Using conductive heat to dry, with high thermal efficiency and low energy consumption.

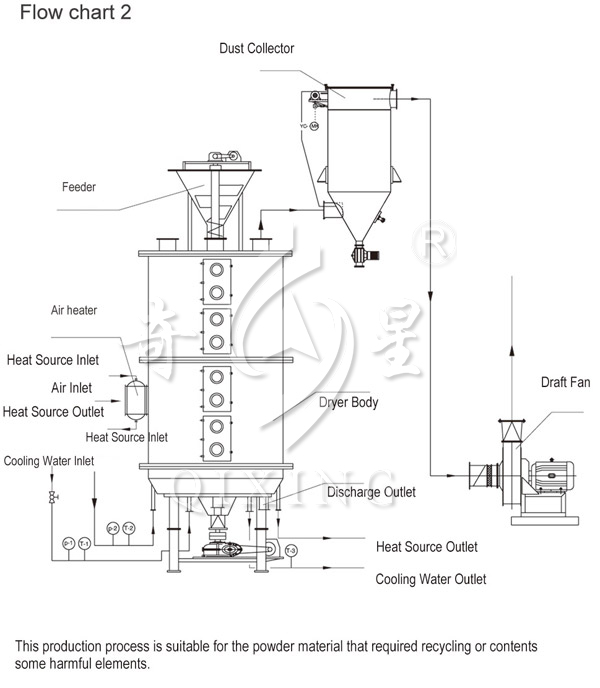

(D) Good operating environment; recyclable solvents and dust emissions all meet the requirements.

◎ Type of constant pressure: due to the low air velocity within the apparatus, and the humidity inside the equipment increases with the height, it is difficult for dust to float to the top of the device, so the exhaust from the outlet on the top contains almost no dust.

◎ Type of sealed: equipped with solvent recovery device, can easily recycle organic solvent contained in the wet gas. Solvent recovery device is simple and has high recovery rate. For flammable, explosive, toxic and easy oxidized materials, nitrogen can be used as the gas carrying moisture to conduct closed loop, to make it safe to operate. It is especially suitable for drying of flammable, explosive and toxic materials.

◎ Type of vacuum: tray dryer operated under vacuum is especially suitable for drying heat-sensitive materials.

(E) Easy installation and small covering area

◎ The dryer leaves the factory and is transported as a whole. What you need to do is just to hoist it into position. It is very easy to be installed.

◎ Because the drying tray is arranged in layers and installed vertically, even large drying area still consumes little area.

◎ With the heat transfer surface. In the axial zone, materials have low temperature, low humidity and small mixing gradient so as to ensure the stability of the process.

TECHNICAL CHARACTERISTICS

(A) Drying Tray

◎ Design pressure: generally 0.4MPa, up to 1.6MPa.

◎ Maximum operating pressure: generally≤0.4MPa, up to 1.6MPa.

◎ Heating medium: steam, hot water, thermal oil. When the temperature of drying tray is 100 ℃, it uses hot water to do heat; hen the temperature reaches 100℃~150℃, it uses saturated steam≤0.4MPa or superheated steam to do heat; when the temperature is 150℃ ~320℃ it uses heating conducting oil to do heat; when the temperature surpasses 320℃, it uses electric, oil or molten salt to do heat.

(B) Material transport system

◎ Rotate speed of main spindle: 1-10 rpm, electromagnetism or variable frequency can achieve stepless speed.

◎ Rake arm: each drying tray has 2 to 8 rake arms fixed on the spindle.

◎ Rake leaves: spliced on the rake arm, it can float with the tray to keep in contact with materials. It has many forms.

◎ Roller: for materials easy to get caked or requiring drying, a roller in appropriate place can enhance heat transfer and drying process.

(C) Three types of constant pressure, sealed and vacuum

◎ Type of constant pressure: cylindrical or octagonal, two structures of whole and dimidiate. Main channel for heating medium can both be inside or outside the shell.

◎ Type of sealed: cylindrical. It can withstand the internal pressure of 5 Kpa. Main channel for heating medium can both be inside or outside the shell.

◎ Type of vacuum: cylindrical. Its design pressure is 0.1 Mpa. Main channel for heating medium is inside the shell.

(D) Air heater

◎ Generally it is used in the case of a large amount of evaporation to increase drying efficiency.

APPLICAITON

Organic chemicals, inorganic chemicals, medicine, food, forage, fertilizer.

TECHNICAL PARAMETERS

|

Item Model |

Diameter (mm) |

Height (mm) |

Drying Area (m2) |

Power (kw) |

|

1200/4 |

Φ1850 |

2718 |

3.3 |

1 |

|

1200/6 |

3138 |

4.9 |

||

|

1200/8 |

3558 |

6.6 |

1.5 |

|

|

1200/10 |

3978 |

8.2 |

||

|

1200/12 |

4398 |

9.9 |

2.2 |

|

|

1500/6 |

Φ2100 |

3022 |

8.0 |

|

|

1500/8 |

3442 |

10.7 |

||

|

1500/10 |

3862 |

13.4 |

||

|

1500/12 |

4282 |

16.1 |

3.0 |

|

|

1500/14 |

4702 |

18.8 |

||

|

1500/16 |

5122 |

21.5 |

||

|

2200/6 |

Φ2900 |

3319 |

18.5 |

|

|

2200/8 |

3739 |

24.6 |

||

|

2200/10 |

4159 |

30.8 |

4.0 |

|

|

2200/12 |

4579 |

36.9 |

||

|

2200/14 |

4999 |

43.1 |

5.5 |

|

|

2200/16 |

5419 |

19.3 |

||

|

2200/18 |

5839 |

55.4 |

7.5 |

|

|

2200/20 |

6259 |

61.6 |

||

|

2200/22 |

6679 |

67.7 |

11 |

|

|

2200/24 |

7099 |

73.9 |

||

|

2200/26 |

7519 |

80.0 |

|

Item Model |

Diameter (mm) |

Height (mm) |

Drying Area (m2) |

Power (kw) |

|

2500/6 |

Φ3150 |

3319 |

26.3 |

3 |

|

2500/8 |

3739 |

35 |

||

|

2500/10 |

4159 |

43.8 |

5.5 |

|

|

2500/12 |

4579 |

52.5 |

||

|

2500/14 |

4999 |

61.3 |

7.5 |

|

|

2500/16 |

5419 |

70 |

||

|

2500/18 |

5839 |

78.8 |

11 |

|

|

2500/20 |

6259 |

87.5 |

||

|

2500/22 |

6679 |

96.3 |

||

|

2500/24 |

7099 |

105 |

13 |

|

|

2500/26 |

7519 |

113.8 |

||

|

3000/8 |

Φ3800 |

4050 |

48 |

11 |

|

3000/10 |

4650 |

60 |

||

|

3000/12 |

5250 |

72 |

||

|

3000/14 |

5850 |

84 |

||

|

3000/16 |

6450 |

96 |

||

|

3000/18 |

7050 |

108 |

13 |

|

|

3000/20 |

7650 |

120 |

||

|

3000/22 |

8250 |

132 |

||

|

3000/24 |

8850 |

144 |

||

|

3000/26 |

9450 |

156 |

15 |

|

|

3000/28 |

10050 |

168 |

STRUCTURE SCHEMATIC

-

/upload/20171018/201710181044154576.jpg

-

/upload/20171018/201710181044154576.jpg

-

/upload/20171018/201710181044154576.jpg

- 2018-05-11 > Tow CT-C Hot Air Circulation Ovens Manufactured by Our Company Were Exported to Bangladesh

- 2018-04-25 > 2018 (Spring) China International Pharmaceutical Machinery Exposition

- 2018-02-23 > New Year Begins a New Journey

- 2017-10-04 > 2017(Autumn) Professional Pharmaceutical Machinery Exhibition in China

- 2017-06-24 > Xinggan Drying Successfully Participated in the 17th Pharmaceutical Raw Materials Exhibition

- 2017-04-22 > 2017(Spring) Professional Pharmaceutical Machinery Exhibition in Qingdao