CT、CT-C Series Hot Air Circulating Oven

CT、CT-C Series Hot Air Circulating Oven

CT、CT-C Series Hot Air Circulating Oven

INTRODUCTION

INTRODUCTION

CT-C hot air circulating oven uses is equipped with low-noise and thermostable axial flow fan and automatic temperature control system. The entire circulatory system is sealed, improving the thermal efficiency of oven from traditional 3-7% in drying room to the current 35-45%, with the highest thermal efficiency up to 50%. The design success of CT-C hot air circulating oven make our hot air circulation oven has reached the advanced level at home and abroad. It has saved a lot of energy for our country and improved the economic efficiency of enterprises. In 1990, Chinese Pharmaceutical Administration has released industry standard, unifying the type to be RXH.

National Industry Standard Model

◎ Heating sources include steam, electricity, far infrared, dual-use of steam and electricity, all for users to choose.

◎ Using temperature: steam heating 50 ~ 140℃, the highest 150℃.

◎ Electricity, far infrared temperature 50 ~ 350℃.

◎ It is equipped with automatic control system and computer control system for users to choose.

◎ Commonly used steam pressure 0.02-0.8Mpa (0.2 ~ 8kg / ㎡).◎ It is equipped with electric heating, valued 15KW calculated according to type I, practical 5-8kw / h.

◎ If there is any special requirement please specify in order.

◎ Price of non-standard oven is negotiable.

◎ Please specify in order if using temperature is more than 140℃ or less than 60℃.

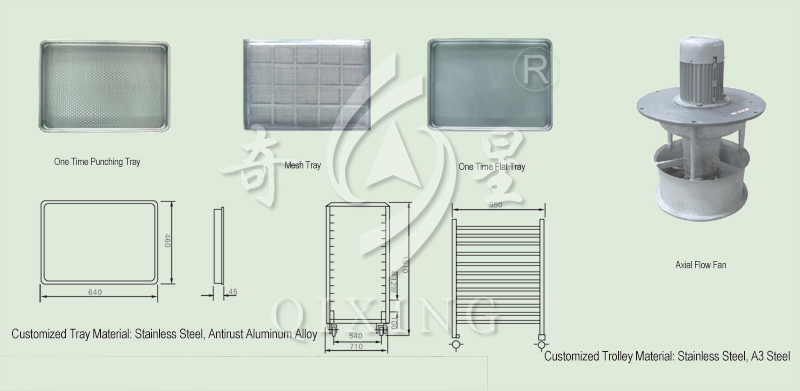

◎ Our baking car and baking tray are in uniform size, so they are interchangeable.

◎ Baking tray size: 460 × 640 × 45 (mm).

FEATURES

◎ Most of hot air loop inside the box so it is high thermal efficiency and energy-saving.

◎ It uses forced ventilation, with adjustable air divider plate in the box.

◎ The materials are dried uniformly. Heating sources offer a wide choice of steam, electricity, far infrared, and so on.

◎ Machine has low noise, auto-controlled temperature and convenient installation and maintenance and is stable in operation.

◎ It has wide APPLICATION and can be used to dry various materials, so it is a commonly used drying device.

APPLICAITON

It is suitable for heat curing and drying and dehydration of materials and products of pharmaceutical, chemical, food, agricultural, aquatic, light industry and heavy industry, such as bulk drug, crude drug, Chinese medicine decoction pieces, extractums, powders, granules, electuaries, water-bindered pills, packing bottle, pigment dyes, dehydrated vegetables, dried fruit, sausages, plastic resin, electric elements, drying varnish, and so on.

ACCESSORIES

| Model |

Field Standaed Model |

Evaporation Area (m2) |

Effective Volume (m³) |

Drying |

Radiator Area (m2) |

Steam |

Elactric |

Fan Volume (m³/h) |

Fan power |

Temperature Difference Inside the Oven(c) |

Oveall Dimensions w*d*h(mm) |

Accessories |

Total Weight (KG) |

|

| Drying Cart(Set) | Drying Pallet(pc) | |||||||||||||

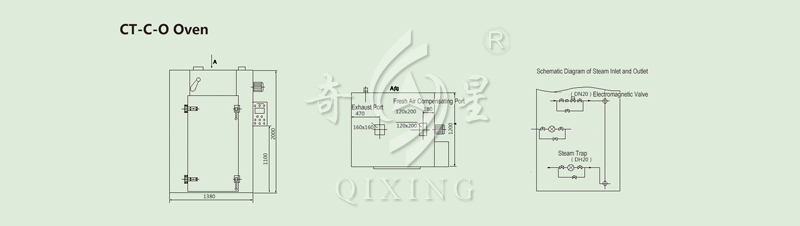

| CT-C-O | EXH-7-C | 7.1 | 1.3 | 60 | 15 | 15 | 6-9 | 4510 | 0.45 | ±1 | 1380*1200*2000 | 1 | 24 | 820 |

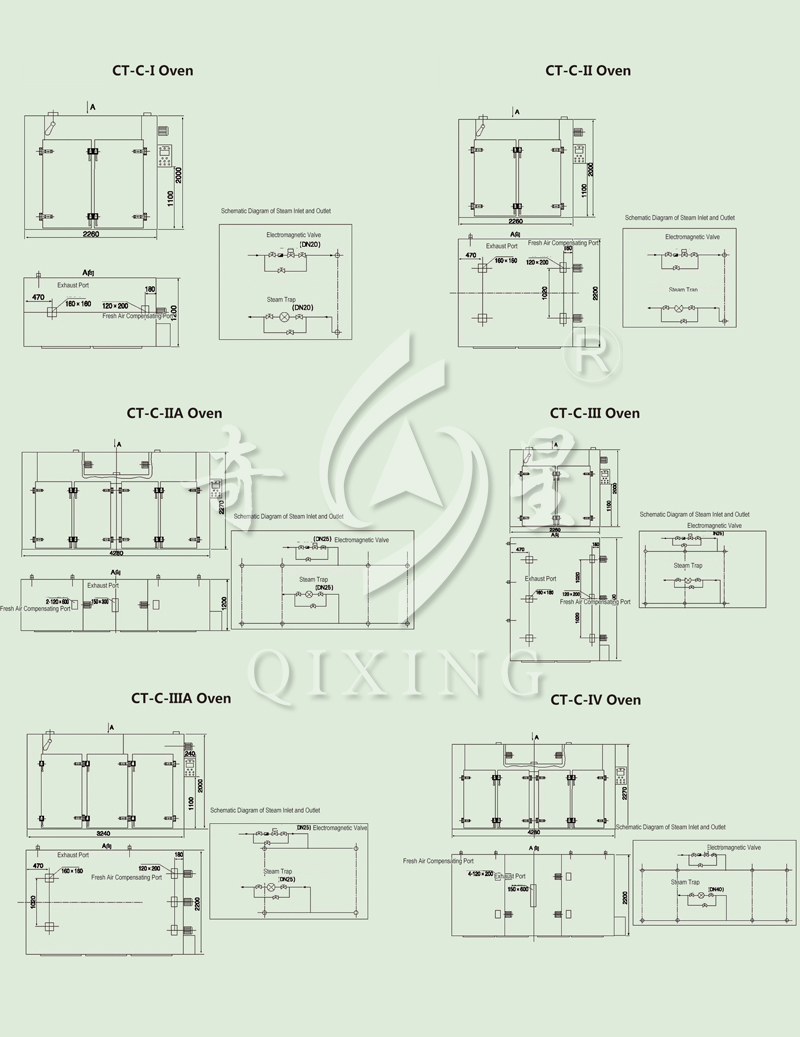

| CT-C-Ⅰ | EXH-14-C | 14.1 | 2.6 | 120 | 23 | 20 | 15 | 4510 | 0.45 | ±2 | 2260*1200*2000 | 2 | 48 | 1580 |

| CT-C-Ⅱ | EXH-27-C | 28.3 | 4.9 | 240 | 48 | 40 | 30 | 9020 | 0.45*2 | ±2 | 2260*2200*2000 | 4 | 96 | 1800 |

| CT-C-ⅠA | EXH-27-C | 28.3 | 4.9 | 240 | 48 | 40 | 30 | 9020 | 0.45*2 | ±2 | 4280*1200*2270 | 6 | 96 | 1880 |

| CT-C-Ⅲ | EXH-41-C | 42.4 | 7.4 | 360 | 72 | 60 | 45 | 13530 | 0.45*3 | ±2 | 2260*3200*2000 | 6 | 144 | 2100 |

| CT-C-ⅢA | EXH-41-C | 42.4 | 7.4 | 360 | 72 | 60 | 45 | 13530 | 0.45*3 | ±2 | 3240*2200*2000 | 8 | 144 | 2210 |

| CT-C-Ⅳ | EXH-54-C | 56.5 | 10.3 | 480 | 96 | 80 | 60 | 18040 | 0.45*4 | ±2 | 4280*1200*2375 | 5 | 192 | 2800 |

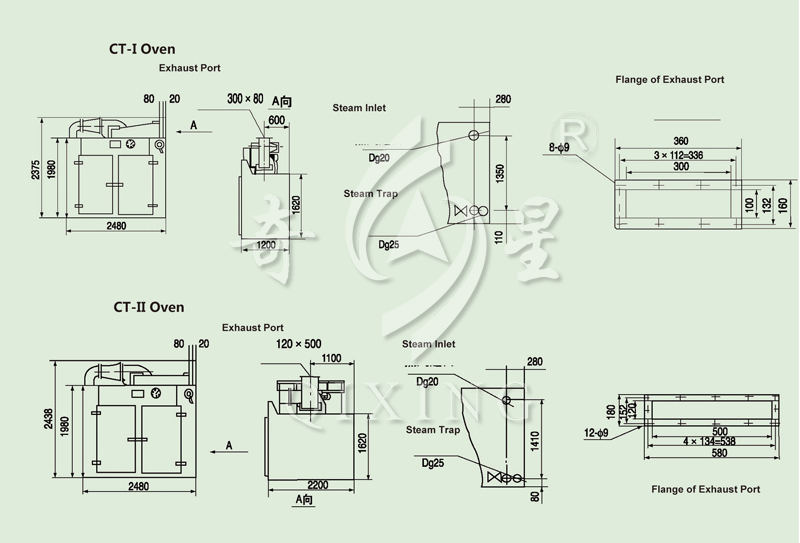

| CT-Ⅰ | EXH-14-B | 14.1 | 2.6 | 120 | 23 | 20 | 15 | 1414 | 1.1 | ±2 | 2480*1200*2375 | 2 | 48 | 1220 |

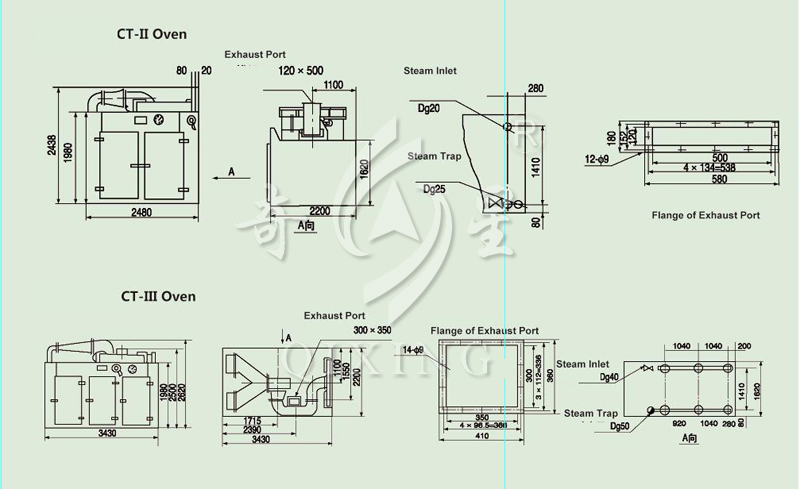

| CT-Ⅱ | EXH-27-B | 28.3 | 4.9 | 240 | 48 | 40 | 30 | 5230 | 1.1 | ±2 | 2480*2200*2438 | 4 | 96 | 1530 |

| CT-Ⅲ | EXH-41-B | 42.4 | 7.4 | 360 | 72 | 60 | 45 | 9800 | 2.2 | ±2 | 2430*2200*2620 | 6 | 144 | 2100 |

| CT-Ⅳ | EXH-54-B | 56.5 | 10.3 | 480 | 96 | 80 | 60 | 9800 | 2.2 | ±2 | 4460*2200*2620 | 8 | 182 | 2300 |

STRUCTURE SCHEMATIC

-

CT、CT-C Series Hot Air Circulating Oven

-

CT、CT-C Series Hot Air Circulating Oven

-

CT、CT-C Series Hot Air Circulating Oven

-

CT、CT-C Series Hot Air Circulating Oven

-

CT、CT-C Series Hot Air Circulating Oven

- 2018-05-11 > Tow CT-C Hot Air Circulation Ovens Manufactured by Our Company Were Exported to Bangladesh

- 2018-04-25 > 2018 (Spring) China International Pharmaceutical Machinery Exposition

- 2018-02-23 > New Year Begins a New Journey

- 2017-10-04 > 2017(Autumn) Professional Pharmaceutical Machinery Exhibition in China

- 2017-06-24 > Xinggan Drying Successfully Participated in the 17th Pharmaceutical Raw Materials Exhibition

- 2017-04-22 > 2017(Spring) Professional Pharmaceutical Machinery Exhibition in Qingdao