XSG SERIES SPIN FLASH DRYER

XSG SERIES SPIN FLASH DRYER

WORKING PRINCIPLE

The hot air enters into the bottom of the dryer in tangent direction. Under the driving of the stirrer, a powerful rotating wind field is formed. Paste materials go into the dryer via screw feeder, and dispersed by impact, friction and shearing force under the powerful high-speed rotating impeller; bulk materials immediately get smashed, in fully contact with hot air in order to get heated and dried. Then the dehydrated materials rise with hot air. A hierarchical ring will make large particles retentate, while exhaust small particles out of dryer from center of the ring, recovered by cyclone separator and deduster. The bulk materials or materials without being fully dryer will be thrown to the wall under centrifugal force and drop to the bottom again to be smashed and dried.

The hot air enters into the bottom of the dryer in tangent direction. Under the driving of the stirrer, a powerful rotating wind field is formed. Paste materials go into the dryer via screw feeder, and dispersed by impact, friction and shearing force under the powerful high-speed rotating impeller; bulk materials immediately get smashed, in fully contact with hot air in order to get heated and dried. Then the dehydrated materials rise with hot air. A hierarchical ring will make large particles retentate, while exhaust small particles out of dryer from center of the ring, recovered by cyclone separator and deduster. The bulk materials or materials without being fully dryer will be thrown to the wall under centrifugal force and drop to the bottom again to be smashed and dried.

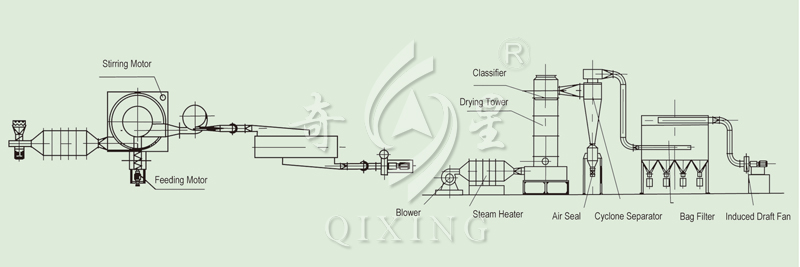

STRUCTURE SCHEMATIC

FEATURES:

◎ Dynamic integration of cyclone, fluidized, spouted and grinding classification technologies.

◎ Equipments are compact and small-sized, enabling high efficiency and continuous production, achieving "small equipment, large-scale production".

◎ Great drying intensity, low energy consumption, high thermal efficiency.

◎ Short material residence time, good product quality, available for drying heat sensitive materials.

◎ Negative or slightly negative pressure operation, good impermeability, high efficiency, eliminating environmental pollution.

TECHNICAL PARAMETERS

|

Model/Item |

XZG-2 |

XZG-4 |

XZG-6 |

XZG-8 |

XZG-10 |

XZG-12 |

XZG-16 |

XZG-20 |

|

Tower Diameter (mm) |

200 |

400 |

600 |

800 |

1000 |

1200 |

1600 |

2000 |

|

Air Volume (m³/h) |

350-500 |

1150-2000 |

2450-4500 |

4450-7550 |

7000-12500 |

10000-20000 |

18000-36000 |

28200-56500 |

|

Water Evaporation (kg/h) |

12-17 |

40-70 |

80-150 |

150-250 |

230-425 |

300-600 |

600-1000 |

1000-1500 |

|

Total Power (kw) |

10 |

20 |

40 |

65 |

85 |

105 |

150 |

230 |

|

Max. Equipment Height (m) |

4.0 |

4.8 |

5.8 |

6.5 |

7.1 |

7.8 |

8.8 |

10.1 |

|

Occupied Area (㎡) |

15 |

20 |

28 |

35 |

40 |

52 |

80 |

150 |

Note:

1. The evaporated amount of moisture is calculated when the temperature of inlet and outlet are180℃;

2. Besides the models above mentioned, special specification can also be made as request;

3. The equipped capacity above mentioned is standard. The power can also be decreased in accordance with pracitcal condition.

Raw Material Example & Characteristics (based on Model XSG-6)

|

Raw Material Item |

Stearate Acid |

Aluminum Hydroxide |

Zinc Carbonate |

Monosultap |

TMTD |

DSDAcid |

Red Iron Oxide |

AntimonyDioxide |

CuprousChloride |

White Carbon Black |

|

Inlet Air Temperature (℃) |

150 |

180 |

150 |

120 |

140 |

150 |

200 |

180 |

200 |

280 |

|

Primary Moisture (%) |

80 |

55 |

80 |

30 |

65 |

60 |

60 |

45 |

30 |

85 |

|

Final Moisture (%) |

0.5 |

1.5 |

1.0 |

1.0 |

0.5 |

0.5 |

0.5 |

1.0 |

3.0 |

5.0 |

|

Practical Drying Capacity (kg/h) |

140-160 |

250-280 |

130-170 |

80-110 |

80-120 |

80-120 |

300-350 |

280-320 |

290-310 |

250-300 |

|

Raw Material Item |

Accelerant |

Oil-soluble Ink |

Metabolic Acidosis MnZn |

Phthalocyanine Blue |

CalciumCitrate |

Superfine Calcium Carbonate |

Mud Additives |

Sodium Dichloroisocyanurate |

Sodium

Isocyanurate |

|

Inlet Air Temperature (℃) |

150 |

150 |

120 |

150 |

140 |

160 |

200 |

180 |

150 |

|

Primary Moisture (%) |

60 |

45 |

30 |

55 |

40 |

70 |

75 |

25 |

30 |

|

Final Moisture (%) |

0.5 |

2.0 |

1.0 |

1.0 |

1.0 |

1.5 |

5.0 |

0.2-2 |

1.0 |

|

Practical Drying Capacity (kg/h) |

80-110 |

350-380 |

120-150 |

160-180 |

300-350 |

430-470 |

290-310 |

80-120 |

90-150 |

-

XSG SERIES SPIN FLASH DRYER

-

XSG SERIES SPIN FLASH DRYER

-

XSG SERIES SPIN FLASH DRYER

-

XSG SERIES SPIN FLASH DRYER

-

XSG SERIES SPIN FLASH DRYER

-

XSG SERIES SPIN FLASH DRYER

- 2018-05-11 > Tow CT-C Hot Air Circulation Ovens Manufactured by Our Company Were Exported to Bangladesh

- 2018-04-25 > 2018 (Spring) China International Pharmaceutical Machinery Exposition

- 2018-02-23 > New Year Begins a New Journey

- 2017-10-04 > 2017(Autumn) Professional Pharmaceutical Machinery Exhibition in China

- 2017-06-24 > Xinggan Drying Successfully Participated in the 17th Pharmaceutical Raw Materials Exhibition

- 2017-04-22 > 2017(Spring) Professional Pharmaceutical Machinery Exhibition in Qingdao