DSH Series Double-spiral Conical Mixer

DSH Series Double-spiral Conical Mixer

DSH Series Double-spiral Conical Mixer

INTRODUCTION

INTRODUCTION

DSH double-spiral conical mixer is a new, high-efficiency and high-precision mixer which is well adopted in powdery material mixing in industries like pharmacy, chemicals and fertilizer and so on. The rotation process is finished by electric machine and CYCLO. The dissymmetrical agitation by twin screw will enlarge the agitation scale and accelerate the mixing rate. It is more suitable for those materials with unbalanced proportion or large content.

WORKING PRINCIPLE

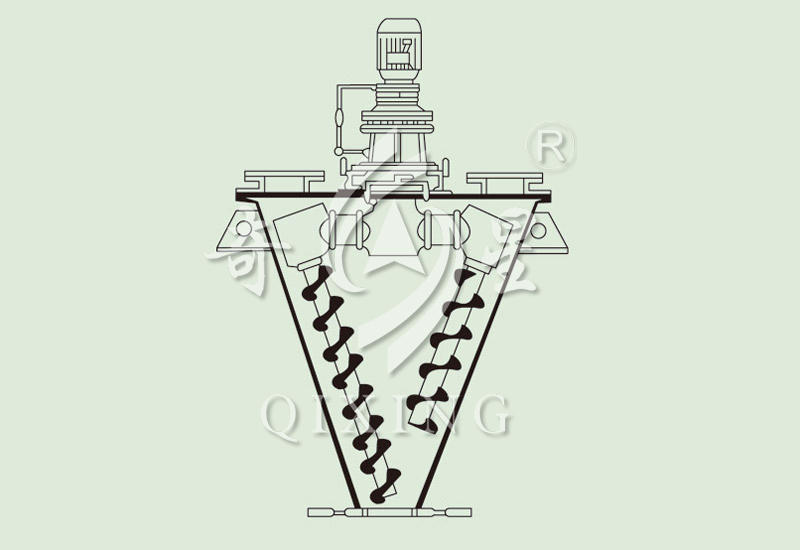

Spiral revolution and rotation will lead to compound motion of material in vertebral body in four major forms. The first is helix’s revolution around internal wall which enables material to conduct circular motion. The second is helix’s rotation which leads to the spiral rise of material from its bottom. The third is the compound motion of spiral revolution and rotation which absorb some materials into the inner wall of spiral cylinder and those materials, under the centrifugal force made by the spiral rotation, will be discharged towards vertebral diameter. The forth is that the rising materials will fall due to gravity. Those four motions happen simultaneously so as to achieve the uniform blend.

FEATURES

◎ In order to meet the demand of technology, fly-cutter and spray atomizer could be equipped.

◎ Manual mode and pneumatic mode are available in bleeder valve.

◎ Stronger motor power could be used to process special materials.

STRUCTURE SCHEMATIC

It is suitable for chemical industry, pharmaceutical industry, pesticide, dyestuff, petroleum industry, metallurgical industry and construction material and so on. Meanwhile, it is also adopted in the blending process of powder and powder (solid - solid), of powder and liquid (solid - liquid) and of liquid and liquid (liquid - liquid), reaction, drying and cooling.

TECHNICAL PARAMETERS

|

Model / Item |

DSH-0.3 |

DSH-0.5 |

DSH-1 |

DSH-2 |

DSH-4 |

DSH-6 |

DSH-10 |

|

Total Volume(m3) |

0.3 |

0.5 |

1 |

2 |

4 |

6 |

10 |

|

Loading Coefficient |

0.4-0.6 |

||||||

|

Diameter of Material(um) |

40-3000 |

||||||

|

Operating Condition |

NPT and dust-free |

||||||

|

Yield Per Batch(kg) |

180 |

300 |

600 |

1200 |

2400 |

3600 |

6000 |

|

Power(kw) |

2.2 |

2.2 |

5.5 |

5.5 |

11 |

20.7 |

30.7 |

|

Mixing Time(min) |

4-10(mixing time of special materials is based on experiment) |

||||||

|

Total Weight(kg) |

500 |

1000 |

1200 |

1500 |

2800 |

3500 |

4500 |

- 2018-05-11 > Tow CT-C Hot Air Circulation Ovens Manufactured by Our Company Were Exported to Bangladesh

- 2018-04-25 > 2018 (Spring) China International Pharmaceutical Machinery Exposition

- 2018-02-23 > New Year Begins a New Journey

- 2017-10-04 > 2017(Autumn) Professional Pharmaceutical Machinery Exhibition in China

- 2017-06-24 > Xinggan Drying Successfully Participated in the 17th Pharmaceutical Raw Materials Exhibition

- 2017-04-22 > 2017(Spring) Professional Pharmaceutical Machinery Exhibition in Qingdao